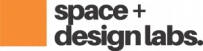

Ever wondered how scientists managed to work safely with dangerous chemicals before modern safety equipment? The evolution of laboratory fume hoods is a fascinating tale of human creativity – starting from basic ventilation systems and leading up to today’s advanced, digitally controlled safety devices.

Table of Contents

What Are Laboratory Fume Hoods?

Basic Definition and Purpose

Think of a laboratory fume hood as your personal bodyguard against harmful chemical vapors. It’s essentially a ventilated enclosure that captures, contains, and removes airborne contaminants from your workspace.

These protective barriers serve multiple critical functions: they shield you from toxic fumes, prevent flammable vapor buildup, and contain chemical spills. Without them, countless researchers would face daily exposure to substances that could cause everything from minor irritation to life-threatening health issues.

Key Components of Modern Fume Hoods

Modern fume hoods are carefully designed systems where every part works together seamlessly. The sash, that sliding front panel, does more than just shield you — it precisely controls the airflow. Inside, specially placed baffles manage how the air moves, while tough, chemical-resistant surfaces stand up to years of harsh chemicals. Many also come with built-in linings, safety outlets, and emergency wash stations for added protection.

Another integral part of fume hood is the presence of proper exhaust system in the form of centrifugal blower which helps in removing airborne contaminants from the lab.

The Early Days of Laboratory Safety

Pre-Industrial Chemistry Practices

Before the industrial revolution, early chemists worked under conditions that would horrify today’s safety professionals. Medieval alchemists relied on nothing more than open windows for ventilation, essentially playing chemical roulette with their health.

These pioneers mixed unknown substances and inhaled whatever vapors resulted. Many suffered chronic poisoning from mercury, lead, and other toxins. The phrase “mad as a hatter” actually comes from hat makers who used mercury and gradually developed neurological symptoms from exposure.

Makeshift Ventilation Solutions

As chemistry evolved from mystical practice to systematic science, researchers began recognizing ventilation needs. Early attempts were remarkably crude – positioning work tables near windows, hoping winds would carry vapors away. Some built simple chimneys above work areas, relying on hot gases rising naturally.

These systems were unreliable, weather-dependent, and often ineffective. But they represented humanity’s first systematic attempts at laboratory safety – the humble beginnings of what would become sophisticated protection systems.

The 19th Century: Foundation Years

Industrial Revolution’s Impact

The industrial revolution didn’t just transform manufacturing – it revolutionized chemistry itself. Factory chemists working with large quantities of dangerous materials couldn’t rely on informal safety practices. Industrial hygiene emerged as a distinct field, driven by the economic reality that healthier workers were more productive.

Gas lighting and electric power provided new opportunities for mechanical ventilation. Engineers could now power fans consistently, regardless of weather conditions. This technological leap laid the groundwork for truly effective laboratory ventilation systems.

First Documented Designs

The first recorded use of fume hoods dates back to the mid-19th century, when they began appearing in laboratories across Germany and Britain. One of the first was installed at the University of Edinburgh in 1869 – a wooden enclosure with a hinged front panel and simple exhaust chimney.

German laboratories, particularly those in the pharmaceutical industry, led many innovations. They developed some of the first mechanically ventilated hoods using steam-powered fans.

Early 20th Century Developments

Standardization Efforts

The early 1900s marked systematic efforts to standardize laboratory safety equipment. Professional organizations developed recommendations for laboratory design. Universities began sharing best practices, leading to uniform approaches to hood installation. The concept of “standard” sizes emerged, making it easier for manufacturers to produce equipment for multiple customers.

Introduction of Mechanical Ventilation

Later on electric power revolutionized the laboratory ventilation. Electric motor powered fans consistently and reliably enabled centralized systems to serve as multiple hoods.. However, engineers quickly discovered that effective ventilation required more than powerful fans – airflow patterns, face velocities, and contaminants.

Fan technology evolved significantly during this period. More efficient designs moved larger air volumes while consuming less energy. Variable-speed controls allowed operators to adjust airflow based on specific requirements, improving both safety and efficiency.

Mid-20th Century Innovations

Post-War Scientific Boom

In the mid of 20th century government funding increased many folds, leading to numerous new laboratory facilities. This boom drove rapid innovations in safety equipment, including significant fume hood advances.

New synthetic chemicals and radioactive materials highlighted the need for sophisticated containment systems. Universities expanded programs to meet growing demand for trained scientists, driving demand for efficient and cost-effective hood systems.

OSHA and Safety Regulations

The establishment of OSHA (Occupational Safety and Health Administration) in 1971 marked a watershed moment for laboratory safety and subsequently it required employers to provide safe working conditions, including adequate ventilation. These standards established minimum performance criteria, making compliance mandatory rather than voluntary.

These safety regulations created strong economic incentives for proper safety equipment. The potential costs of violations, compensation claims, and liability made high-quality fume hoods sound business investments rather than optional expenses.

Modern Fume Hood Technology

Digital Controls and Monitoring

The fume hoods we use today are a world apart from those early versions seen in 19th-century labs. Modern models are equipped with digital systems that constantly track airflow rates, face velocities, and overall performance. These systems automatically adjust fan speeds to keep conditions safe while cutting down on unnecessary energy use.

Real-time monitoring means users get immediate feedback, with alerts if something’s not right — long before it becomes a hazard. Many setups even connect to building management systems, allowing for facility-wide monitoring and control.

Energy Efficiency Has Come a Long Way

Today’s fume hoods are built to save energy without sacrificing safety. Variable Air Volume (VAV) technology adjusts airflow according to how the hood is being used. When idle, it lowers airflow to a safe minimum, dramatically reducing energy consumption.

High-efficiency motors, smart ductwork designs, and energy recovery systems also contribute to improved performance. These systems even capture heat from exhaust air to help condition incoming fresh air, boosting overall energy efficiency.

Specialized Fume Hood Types

Perchloric Acid Hoods

Some tasks require fume hoods with special features. For example, working with perchloric acid is risky because it produces highly corrosive fumes and can leave behind explosive residues. That’s why perchloric acid hoods are built with wash-down systems that regularly clean the ductwork, preventing dangerous buildup. They also use specialised materials and welding methods to ensure maximum safety over time.

Radioisotope Fume Hoods

Radioactive material research requires systems handling both chemical and radiological hazards. These incorporate HEPA filtration, specialized materials, and contamination monitoring. Multiple filtration stages ensure extremely high particle removal efficiency while continuous monitoring tracks radiation levels.

Current Trends and Future Directions

The future lies in the intelligent integration with laboratory automation systems. Smart hoods communicate with other equipment, coordinating operations for optimal safety and efficiency. Artificial intelligence analyzes usage patterns and automatically adjusts performance.Sustainability is increasingly important, with renewable energy integration and lifecycle assessment considerations driving manufacturing improvements.

Frequently Asked Questions

What is the typical lifespan of a modern laboratory fume hood?

A well-maintained modern fume hood typically lasts 15-20 years, depending on usage patterns, maintenance quality, and chemical exposure. Regular maintenance including filter replacements and airflow testing significantly extends lifespan while ensuring consistent safety performance.

What factors should I consider when selecting a new fume hood?

Consider chemical types, workspace dimensions, available utilities, ventilation compatibility, and above all the budget available. Energy efficiency, maintenance requirements, and specialized features like perchloric acid compatibility or radioactive material handling should also influence your decision.

How can I tell if my fume hood is working properly?

You can check your fume hood’s performance by measuring its face velocity — it should typically fall between 80 to 120 feet per minute. You can also use smoke tests to visualize airflow and tracer gases for containment checks. Most newer hoods display real-time airflow data, but it’s still a good idea to have them professionally tested at least once a year.

What’s the difference between a fume hood and a biosafety cabinet?

While both protect users, they serve different purposes. Fume hoods are designed to remove hazardous chemical vapors by venting them outside. Biosafety cabinets, on the other hand, shield both the user and the work from biological contaminants using HEPA filters and carefully controlled airflow. The right choice depends on whether you’re handling chemicals or biological materials.

Is it possible to upgrade an old fume hood with modern technology?

Yes – many older fume hoods can be updated with new controls, Variable Air Volume (VAV) systems, and digital monitoring tools. However, whether it’s worth the investment depends on the hood’s age, condition, and compatibility with newer systems. A professional evaluation can help you decide if an upgrade or a full replacement makes more sense.

Conclusion

The evolution from crude ventilation systems to intelligent, digitally controlled fume hoods represents one of science’s most important safety advances. Each generation took ahead predecessors’ work, creating increasingly sophisticated protection systems that have enabled breakthrough research while protecting countless researchers.

In the modern day scientific challenges, advanced fume hood technology continues to play a crucial role in ensuring research proceeds safely and effectively. The story of fume hood evolution is ultimately about human ingenuity and our commitment to scientific progress through safer research environments.

I’m Arun Kumar Pathak, a professional with 18 years of experience in Quality and Operations management. I hold M.Com, M.A., and PGDIBO degrees. After working with companies like Reliance, GATI, and Vectus, I transitioned to the laboratory field 4 years ago. Currently, I’m the Operations Manager at Space Plus Design Labs Pvt. Ltd., where I collaborate with design and manufacturing teams to manage the production of laboratory furniture, Fume Hoods, and scientific equipment. Also I love to share my experience to create content, that’s way here sharing blog articles.